Embedded Electronics & SCADA Software Development

Smaller, faster and better - these words define the embedded software development. With rapid technology advancements hardware is getting smaller and faster. Software has to rapidly adapt to deliver more and more innovative, secure and reliable solutions based on state of the art hardware. We create or customize the data acquisition software which support and communicate with any kind of PLC , Data Logger , Recorders and any digital or analog instrument products with output in serial port, parallel port, USB and TCPIP. Expected output could be in MODBUS or any custom build ASCII or HEX format. All the software are compatible with 21 CFR rule.

Supervisory control and data acquisition (SCADA) is a system of software and hardware elements that allows industrial organizations to:

- Control industrial processes locally or at remote locations

- Monitor, gather, and process real-time data

- Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software

- Record events into a log file

The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators.

The SCADA concept was developed to be a universal means of remote-access to a variety of local control modules, which could be from different manufacturers and allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distributed control systems in function, while using multiple means of interfacing with the plant. They can control large-scale processes that can include multiple sites, and work over large distances as well as small distance.

SCADA systems are crucial for industrial organizations since they help to maintain efficiency, process data for smarter decisions, and communicate system issues to help mitigate downtime.

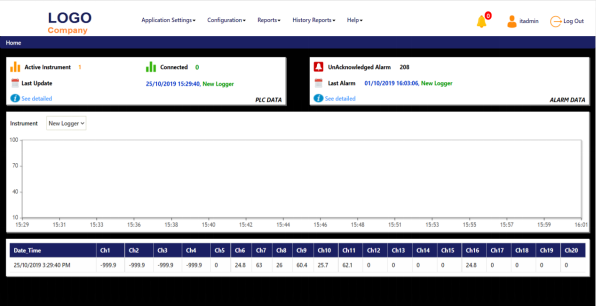

Web Based software.

The basic SCADA architecture begins with programmable logic controllers (PLCs) or remote terminal units (RTUs). PLCs and RTUs are microcomputers that communicate with an array of objects such as factory machines, HMIs, sensors, and end devices, and then route the information from those objects to computers with SCADA software. The SCADA software processes, distributes, and displays the data, helping operators and other employees analyze the data and make important decisions.

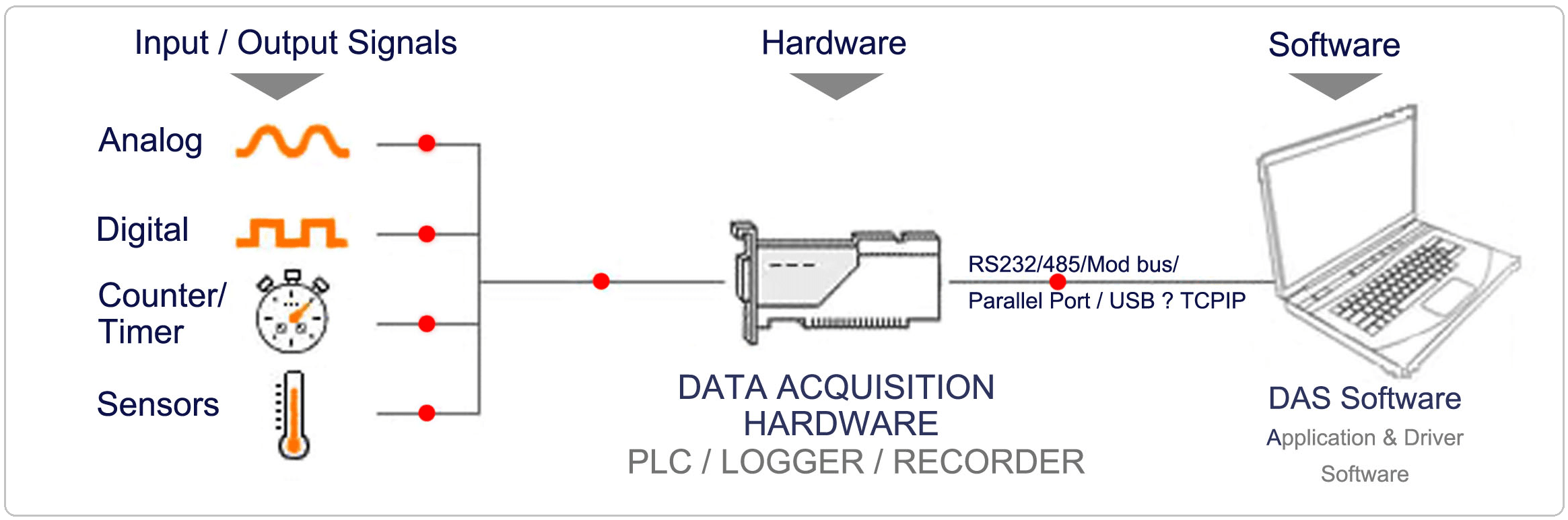

Data Acquisition System (PC Based Software for RS232/485/Modubus /Parallel Port /USB/TCPIP)

Data acquisition systems, as the name implies, are products and/or processes used to collect information to document or analyze some phenomenon. In the simplest form, a technician logging the temperature of an oven on a piece of paper is performing data acquisition. As technology has progressed, this type of process has been simplified and made more accurate, versatile, and reliable through electronic equipment. Equipment ranges from simple recorders to sophisticated computer systems. Data acquisition products serve as a focal point in a system, tying together a wide variety of products, such as sensors that indicate temperature, flow, level, or pressure.

The purpose of data acquisition is to measure an electrical or physical phenomenon such as voltage, current, temperature, pressure, or sound. PC-based data acquisition uses a combination of modular hardware, application software, and a computer to take measurements. While each data acquisition system is defined by its application requirements, every system shares a common goal of acquiring, analyzing, and presenting information. Data acquisition systems incorporate signals, sensors, actuators, signal conditioning, data acquisition devices, and application software.

We create or customised the data acquisition software which support to communicate with any kind of PLC , Data Logger , Recorders and any digital or analog instrument produce output in the serial port ,Parallel port ,USB and TCPIP. Expected output could be in MODBUS or any custom build ASCII or HEX format. All the software are compatible with 21 CFR rule.

Application in

- Pharmaceutical company(Humidity, Temp, Pressure control, storage and its reporting)

- Chemical industry

- Forging industry

- Glass industry

- Manufacturing Industry and all other industry require controlling the parameter.